Corrective

action plan

Dynamic online forms for CAPA processes. Ensure health, safety and quality compliance by digitising and optimising corrective action plan procedures.

Improve health, safety and quality compliance by digitising corrective and preventative action plan (CAPA).

Improve quality control in your corrective action plan with workflow software

Digitalising CAPA processes with workflow software improves quality in many aspects, reduces risk of non-conformance and overall saves time and costs due to increased efficiencies.

From HR managers handling customer complaints or correcting training manuals to Quality Assurance managers correcting defects in products or services, using a good corrective action plan will determine the level of quality control in both business processes as well as the organisation as a whole.

Capture lessons

Learn from today's corrective action plan and prevent future problems and non-conformances proactively.

Eliminate Excel sheets

Manage your entire CAPA process efficiently with digital forms in real time and centralise all the data in a single place.

Standardize CAPA

Identify, address, and prevent recurrence of non-conformance by bringing transparency so that everyone follows the same way.

Easy CAPA reporting

Track & report and monitor progress with a robust CAPA process. Easily share CAPA reports with other stakeholders.

Boost your corrective action plan with a digital CAPA process

Increased regulatory pressures and quality initiatives require you to take a more proactive and automated approach to corrective action plan processes.

Digital corrective action plan can ease the entire CAPA process, reduce risk and accelerate quality control and health and safety.

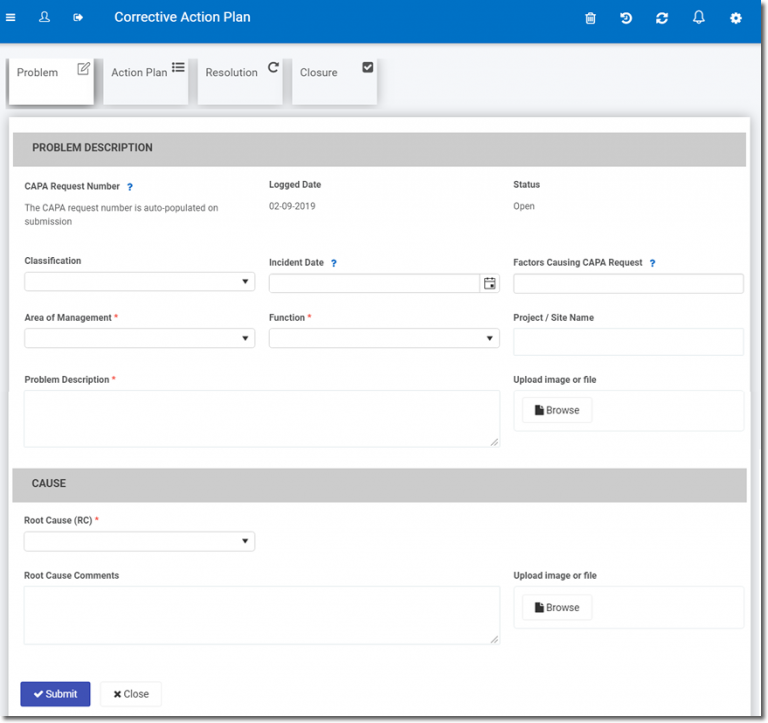

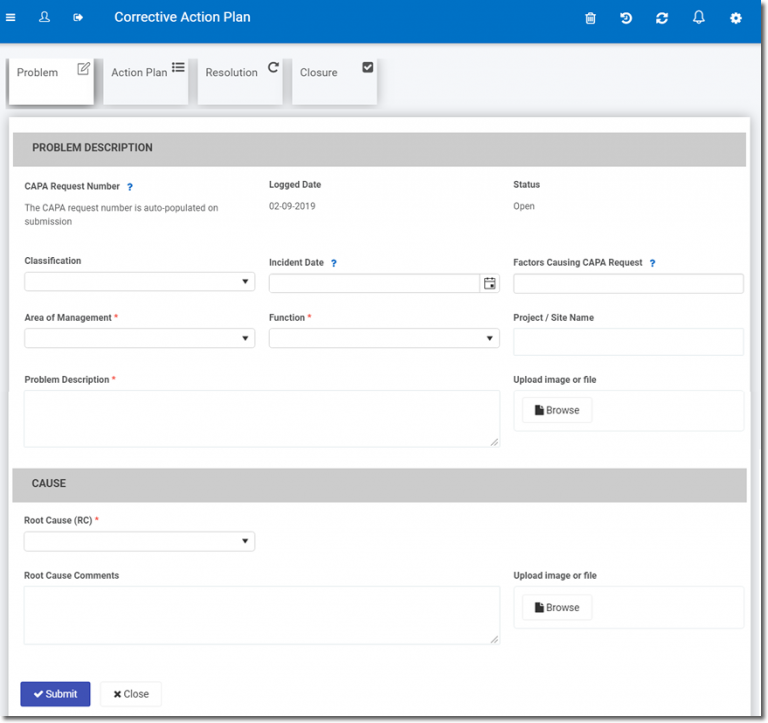

Progress corrective action plan through flexible and effective steps

Simplify the entire approach to your corrective and preventive action plan and reduce the administrative work by transforming the process with workflow software made of critical steps.

- Identify the problem

- Detail the action plan

- Determine resolution process

Prevent future re-occurrence proactively with a digital corrective action plan process

CAPA processes through handy mobile tools enable you to identify and record issues instantly, whether it be a hazardous piece of machinery on a construction site or a customer complaint.

With an effective corrective action plan, you can address non-conformities and take proactive steps to prevent potential problems occuring in the future.

Why digitise your corrective action plan?

Learn how you can digitally transform your corrective action plan.

Inspection checklist

Quality Managers, Quality Engineers can easily implement online site inspection checklists instead of traditional, manual pen-to-paper checklists thanks to Kianda Platform.

Digital incident report

Ensure quality, H&S compliance, improve visibility, documentation, accurate reporting and prevention by tracking key metrics and effectively capturing all accidents / near miss events and more with incident report forms.

Maintenance checklist

Spend less time worrying about how to manage, and more time focused on ensuring business and operational excellence with a Maintenance checklist.

Accelerate digitalisation to deliver an impact today

Want to know how Kianda no-code business process automation platform can help accelerate your digital transformation journey.

Improve quality in your CAPA procedures

Digitalising corrective and preventative action processes with workflow software improves quality, reduces risk of non-conformance and saves time and costs.

Capture lessons

Learn from today's corrective action plan and prevent future problems and non-conformances proactively.

Eliminate Excel sheets

Manage your entire CAPA process efficiently with digital forms in real time and centralise all the data in a single place.

Standardize CAPA

Identify, address, and prevent recurrence of non-conformance by bringing transparency so that everyone follows the same way.

Easy CAPA reporting

Track & report and monitor progress with a robust CAPA process. Easily share CAPA reports with other stakeholders.

Boost your corrective action plan

Increased regulatory pressures and quality initiatives require you to take a more proactive and automated approach to corrective action plan processes.

Digital corrective action plan can ease the entire CAPA process, reduce risk and improve quality, health and safety.

Progress CAPA with effective steps

Simplify your approach to corrective and preventive action and reduce administrative work by transforming the process with workflow software made of critical steps.

- Identify the problem

- Detail the action plan

- Determine resolution process

Proactively prevent future occurences

Digital CAPA processes enable you to identify and record issues in real-time, whether it be hazardous machinery on a construction site or a customer complaint.

With an effective corrective action plan, you can address non-conformities and take proactive steps to prevent potential problems occuring in the future.

Why digitise your corrective action plan?

Learn how to transform and simplify your approach to corrective and preventative action tasks by turning your processes into digital workflows.

Other quality control forms to use

Inspection checklist

Quality Managers, Quality Engineers can easily implement online site inspection checklists instead of traditional, manual pen-to-paper checklists thanks to Kianda Platform.

Digital incident report

Ensure quality, H&S compliance, improve visibility, documentation, accurate reporting and prevention by tracking key metrics and effectively capturing all accidents / near miss events and more with incident report forms.

Maintenance checklist

Spend less time worrying about how to manage, and more time focused on ensuring business and operational excellence with a Maintenance checklist.

Optimise quality control to deliver an impact today

Want to know how Kianda flexible quality management software can help optimise your quality management?